Spin Coating

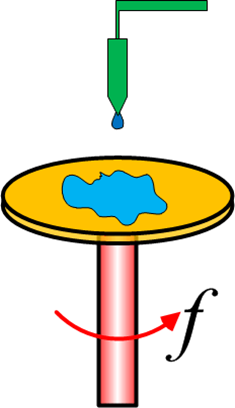

Spin coating is a procedure used to apply uniform thin films to flat substrates. In short, an excess amount of a solution is placed on the substrate, which is then rotated at high speed in order to spread the fluid by centrifugal force. A machine used for spin coating is called a spin coater, or simply spinner (see figure).

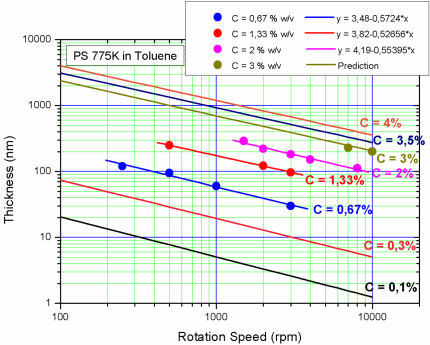

Rotation is continued while the fluid spins off the edges of the substrate, until the desired thickness of the film is achieved. The applied solvent is usually volatile, and simultaneously evaporates. So, the higher the angular speed of spinning, the thinner the film. The thickness of the film also depends on the concentration of the solution and the solvent.

Stages of spin coating

Although different engineers count things differently, there are four distinct stages to the spin coating process.

1. Deposition of the coating fluid onto the wafer or substrate

2. Acceleration of the substrate up to its final, desired, rotation speed

3. Spinning of the substrate at a constant rate; fluid viscous forces dominate the flouid thinning behaviour.

4.Spinning of the substrate at a constant rate; solvent evaporation dominates the coating thinning behavior.

Thickness of film as a function of Rotation speed for various concentrations of Polystyrene (M = 775 kg/mol) in toluene.